Product

Mark-free product identification – The digital fingerprint for your components

How it works

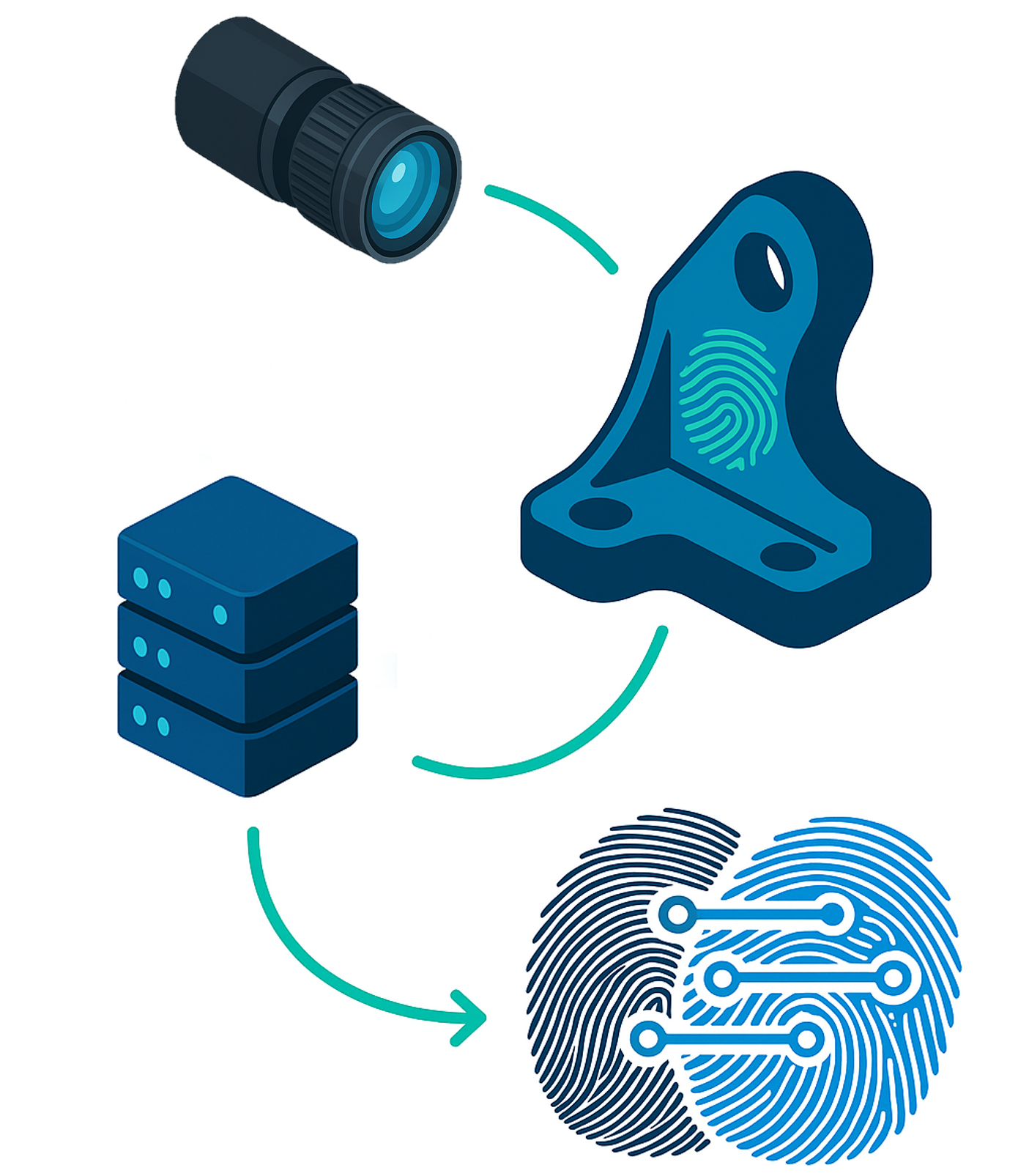

Our technology enables mark-free, unique, forgery-proof, and invisible identification of components. Each component has a unique signature, which we use for identification in the following steps:

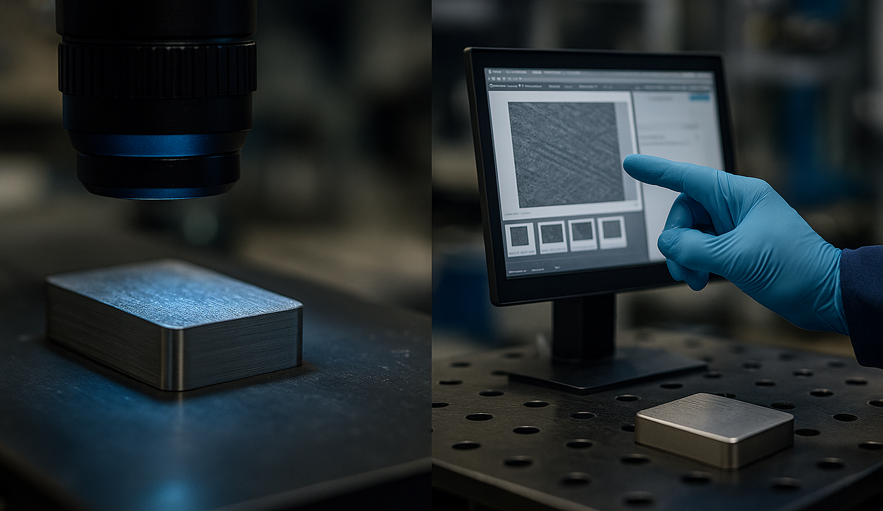

- Capturing the surface structure: An industrial camera is used to create a high-resolution image of the surface structure.

- Extraction of the digital fingerprint: The digital fingerprint is extracted from this image and compared with all entries in a database.

- Precise comparison: First, the database entries are pre-sorted. Then the characteristics of the digital fingerprints are compared geometrically. The number of positive matches determines the certainty of identification of the component.

Our License Offer

Registration and comparison of components

Recording of the individual surface structure of each component and comparison with a database for unique identification.

Plagiarism Protection

Protection against product piracy through unique digital fingerprints that cannot be copied or manipulated.

Visual representation of the database

Intuitive visualization of all stored component data for quick analysis and easy tracking.

Our Range of Services

Camera Implementation

If you do not yet have a camera in your production facility, we will be happy to install and calibrate one for you—optimally tailored to your production environment.

Connection to ERP/MES

Direct integration of our identification solution into your existing company and production systems.

Consulting

Individual consultation on integration options, process optimization, and long-term data security.

Our Advantages

Traceable

Simplifies quality management and is a prerequisite for digital twins and digital product passports

Forgery-proof

The structure of each surface is unique and cannot be replicated. This makes it possible to clearly distinguish original parts from counterfeits.

Fast

Recording takes less than a second. Compared to conventional marking methods, the time required can be reduced by up to 60%.

Universal

Applicable to solids with a visible surface area of at least 0.25 mm².

Frequently Asked Questions (FAQ)

Technology & Functionality

How does identification without marking work?

Our solution utilizes the natural microstructure of each products surface. Characteristics in the frequency range are extracted by measuring the surface. The pattern is similar to a fingerprint and enables unique recognition. No label, engraving, or additives are necessary.

What is a product's “digital fingerprint”?

This is a pattern of characteristics in the frequency range that are extracted from the microstructure of the surface. The digital fingerprint of the surface is absolutely unique and cannot be reproduced.

Has the technology been scientifically tested?

Yes. The method was developed in several research projects at Leibniz University Hannover and is scientifically validated and protected by a patent.

Anwendung & Integration

Which products can be identified?

In principle, all products with a sufficiently structured surface can be used. The application is independent of the shape, material, or coating.

Do you need special cameras or hardware?

All you need is a standard industrial camera and exposure that highlights the microstructure. No special reader, no laser marker.

How fast is the identification process?

Usually within seconds – ideal for automated production processes.

How complex is integration into existing systems?

Very low. The solution is plug-and-play-compatible and can be integrated into existing IT/OT systems via standardized interfaces.

Safety & Reliability

How forgery-proof is the system?

Extremely secure. The surface structure used for identification is based on stochastic factors and cannot be manipulated or copied. This makes the technology ideal for security-critical applications.

Does identification still work if the device is worn or damaged?

Yes, even with aged or slightly damaged surfaces, identification remains reliable in many cases.

Usage & Trial Period

Can we test the solution on our own products?

Yes. Send us samples. We will test our solution individually and without obligation.

How does a pilot project work?

You send us ten sample products, which we test for suitability for our identification technology.

You are welcome to provide us with information about your application or existing camera systems at this stage.

After analysis, we will provide you with feedback on identification reliability.

Upon request, we will also provide you with:

– an estimate of the implementation costs or

– a demonstrator to illustrate your specific application.